(通讯员王攀攀)近日,我校工学院袁巧霞教授课题组在WaterResearch上发表了题为“Performance evaluation of a solar evaporation system for liquid digestate concentration”的研究论文。该研究开发了一套“太阳能-空气”强化蒸发的沼液浓缩系统,在典型工况下对系统性能进行了评估及环境经济性评价。研究结果为沼液的低成本、高效浓缩提供了新思路。

近年来,随着我国畜牧业的发展,畜禽粪污的安全处理及资源化利用问题倍受人们关注。厌氧消化是农业废弃物资源化利用的一种重要技术手段,它可在处理农业废弃物的同时获得清洁能源,对缓解能源危机及环境污染治理均具有重要意义。然而,随着畜禽粪污厌氧消化技术的推广,厌氧发酵沼液的产生量随之增大,沼液的安全消纳已成为当前中国农业源废弃物污染防治必须要面对和解决的问题。

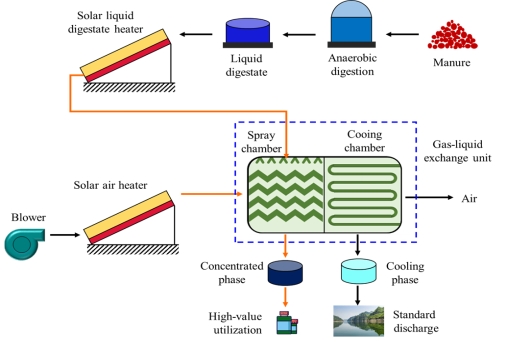

沼液可作为有机肥利用,但养分含量低限制了其消纳半径,以太阳能为热源进行高温浓缩,可以提高沼液的养分浓度,但随着浓缩温度的升高,沼液中游离氨浓度增加,因蒸发损失的养分量也增大。基于此,本研究开发了一套“太阳能-空气”强化蒸发的沼液浓缩系统,该系统以太阳能为热源同时对沼液和空气进行升温,利用太阳能调节空气的载湿能力和沼液的蒸发强度,通过系统工艺和参数的优化强化传热传质,实现沼液的低温高效浓缩,同时协同沼液的酸调节以控制系统总养分的损失。该系统在日平均太阳辐射为773.08W/m2时,沼液浓缩率可达43.33%。当调节沼液初始pH为5时,沼液中的氮以稳定的离子态铵形式存在,使氨氮回收率由原沼液的6.42%提高到78.39%。研究结果还表明,改变系统中沼液流速,可调控喷淋室内沼液与空气的热质交换强度,改善沼液浓缩效果。针对沼液处理规模为100吨/天的沼气工程,其浓缩成本仅为6.8元/吨,远低于目前的膜浓缩成本。相较于以化石燃料为能源的蒸发技术,该系统能减少2.40×105吨的CO2排放,获得3.48×106美元的碳信用。该研究开发了一套经济、环保、高效的沼液浓缩技术,为沼液的高值化利用提供条件。

我校工学院博士研究生王攀攀为论文第一作者,工学院袁巧霞教授为论文通讯作者。该研究得到了国家重点研发计划的资助。

【英文摘要】

The safe and efficient treatment and resource recovery of the large amount of liquid digestate (LD) produced by biogas plants has become an important factor limiting the development of the biogas industry.In this study, a solar evaporationsystem was developed based on low cost, highefficiency, and high nutrient recovery of LD concentration. The effects of different parameters, including solar radiation, LD flowrate, and daily treatment capacity, on the concentration efficiency, nutrient recovery, andthermalefficiency were investigated. Economic andenviroeconomicanalyseswere conducted to comprehensively assess the feasibility and environmental benefits of the systemforlarge-scale biogas plants. The results showed that the higher the solar radiation, the higher the air temperature and its saturation vapor pressure, which led to an increase in the concentration efficiency of LD. The LD concentration efficiency can reach up to 43.33%whenthe average daily solar radiation was773.08 W/m2.High solar radiation also contributed to high LD temperature, leading to an increase in the percentage of free ammonia (NH3)intheLD, which was not conducive to the recovery of ammonia nitrogen (NH3-N).By increasing the LD flow rate, the heat and mass exchange between air and LD in the spray chamber was enhanced, resulting in higher concentration efficiency.The variation of LD flow rate and daily treatmentcapacityhad little effect on nutrient recovery. The recovery of NH3-N and soluble salts in the concentrated phase could be as high as 78.39% and 84.19%, respectively, whentheinitial pH of LD was 5, the air flow rate was 0.03 m3/s, and the LD flow rate was 6 L/min. In addition, the economic analysisindicated that theconcentrationcost of the system in treating a daily LD production of 100 tons was1.08 USD/ton. The solar evaporation system can reduce CO2emissions by 2.40×105tons and earn carbon creditsof3.48×106USD over its lifetime.This study provides a new direction and reference for LD concentration.

论文连接:https://doi.org/10.1016/j.watres.2022.118056

审核人:袁巧霞